academia

“The most advanced ultrasound velocity profiling instrument in the world…”

Non-invasive and high-resolution ultrasonic measurements in complex fluids

• Visualize profiles with over 100 sampling points across a 1 cm measurement distance.

• Measure transient flows with high refresh rates by using onboard FPGA-based data processing.

• Complete on-line and off-line package for data processing, visualization and exporting.

• Signal processing techniques and digital algorithms developed by world experts.

• Complex flow is undisturbed with non-contact sensor installation.

• Extract specific information with access to Raw (RF), Demodulated (IQ) and Processed (FFT) data.

• Medical ultrasound imaging technology can now be used in fluid mechanics or engineering applications.

• Incipientus gives you more control over system parameters, enabling sophisticated measurements.

Ultrasound imaging

Important information about the actual luid and process can be derived by using RF data. Fluid structures, fibre lengths, homogeneity as well as process parameters (e.g. CIP, product changeovers) can be measured using ultrasound imaging.

IncipientusTM enhances the measurement data by using image processing techniques. Artefacts due to electromagnetic noise, pipe vibrations and sensor coupling that influence the image quality are removed.

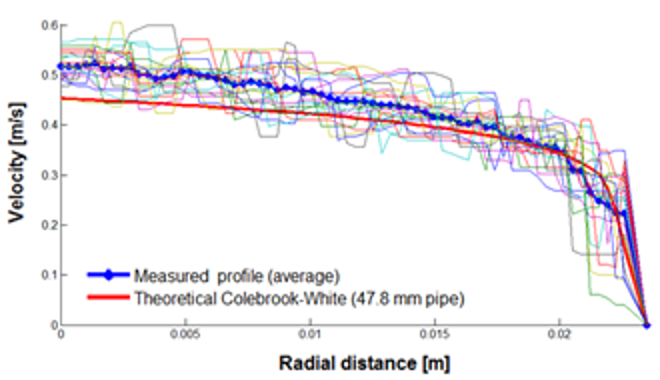

Numerical model validation

Important information about the actual fluid and process can be derived by using RF data. Fluid structures, fibre lengths, homogeneity as well as process parameters (e.g. CIP, product changeovers) can be measured using ultrasound imaging.

IncipientusTM enhances the measurement data by using image processing techniques. Artefacts due to electromagnetic noise, pipe vibrations and sensor coupling that influence the image quality are removed.

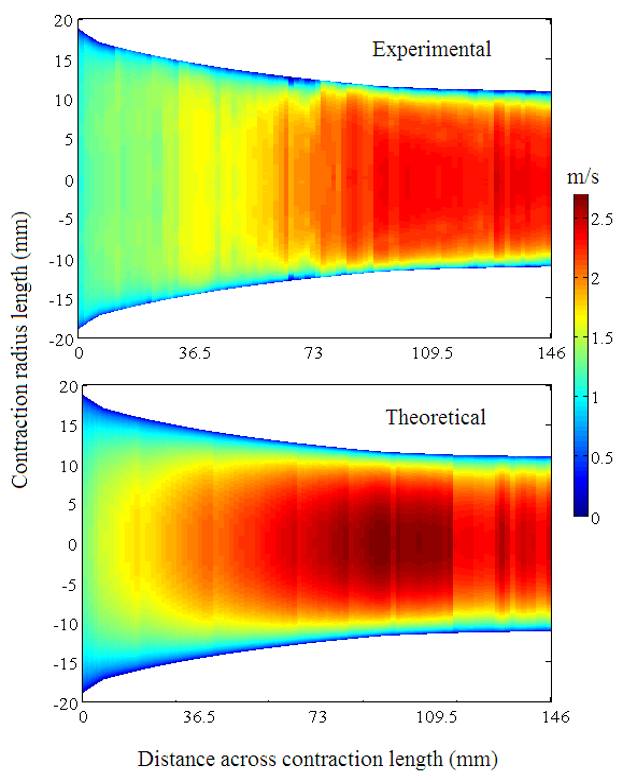

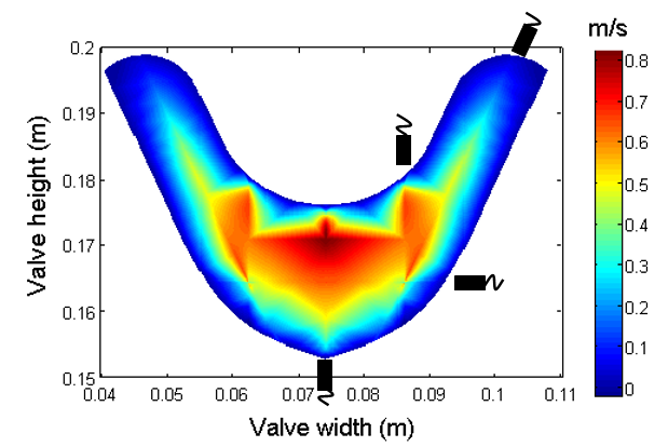

Flow mapping in complex geometries

Flow through complex geometries such as abrupt contractions and enlargements, open channels as well as valves are important problems in fluid dynamics, because they are integral components in pipeline systems. Understanding the energy loss mechanisms in complex geometries is therefore a prerequisite to good engineering design of pipeline systems. There are very few experimental results available for viscous fluids in complex geometries. Most of the complex flows which are encountered in industry can only be studied without disturbing the flow to be measured. UVP is a capable tool to study such flows.

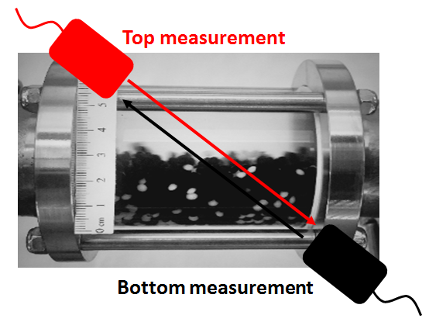

Complex flows – multiphase flow

In the process industries it is often required to pump fluids through a pipeline network from storage facilities to various processing units. Monitoring and understanding the flow behavior of a complex multiphase fluid in the production or pipeline is therefore essential. UVP can be used to detect different flow regimes and the solids-liquid interface in multiphase flow. Experimental data can aid engineers to gain a better understanding of these complex flows and to develop more accurate predictions.

Temporal flow behavior studies

Detailed experiments can be done on spatio-temporal flow conditions using UVP. CFD offers tools to design and predict different dynamic flow situations, but involves a number of assumptions. Important information can be determined from time evolution studies in different applications, for example mixing. To design more efficient processes these flows need to be measured and quantified. CFD is a modelling of the reality, but IncipientusTM UVP is a measurement of the reality.